Project Solutions

THERMOELEMENTS (2)

Published:2011/8/10 20:24:00 Author:Phyllis From:SeekIC

By Thomas Johann Seebeck

Processing the values

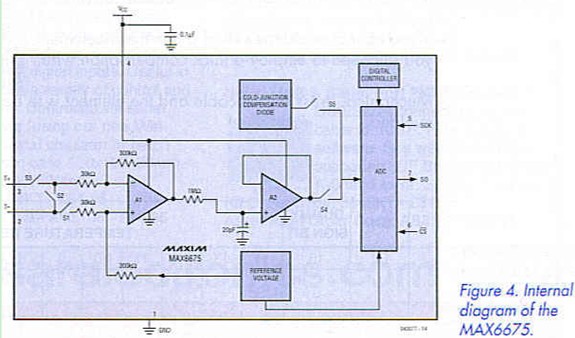

In a previous publication from our archive, ’Fast, Precise Thermometer’ (Eleklor Electronics January 1992), we already proposed a thermoelement application. In that circuit, the comparison point compensation was handled by discrete components. Today, the semiconductor industry supplies complete, dedicated converters in a chip. An example is the MAX6675, a 12-bit A/D converter with SPI interface (and complementary control) and a noise-suppressing, buffered differential measurement amplifier in front of it (not shown). The internal diagram (Figure 4) also reveals a compensation diode that captures the temperature at the comparison point and so provides the necessary correction of the measured value. The MAX6675 is ready for measurement point temperatures from 0 =C to 1023.75 CC and is capable of compensating comparison point temperatures of -20 to +85 =C. This results in an impressive resolution of 0.25 ;C. By comparison, another IC from the series, the MAX7774 with 10-bit resolution achieves a resolution of 1 °C.

SPI

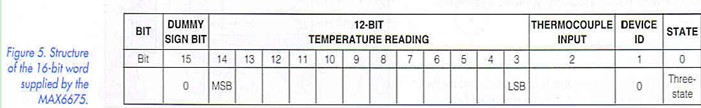

The ’cleaned’ measurement value is finally digitized by the A/D converter, serialized, and may be requested by a microcontroller (read-only). The extremely simple SPI protocol supplies a 16-bit word in response to a clock signal. Not much needs to be said about the timing, as lots of literature on the protocol is available from Internet. Figure 5 shows the structure of the 16-bit word. A sequence of zeroes at positions 3 (LSB) through 14 (MSB) means a temperature of 0 CC, while twelve ones indicate 1023.75 "C which is just another rather uncomfortable level.

Bit 2 has a special function. It is normally low, but will carry a High when the thermocouple input is open, for example, as the result of a cable malfunction. This will only work, however, when the T- input is grounded (as close as possible to the GND connection).

Practical use

A number of requirements should be fulfilled in order to achieve maximum accuracy.

- Self-heating of the MAX6675 should be avoided. Provide for sufficient ventilation and large ground planes.

- The thicker the wire used for the thermoelement and the compensation line, the smaller the risk of measured values being corrupted by the wire resistance(s).

- If you cannot avoid the use of a thin thermoelement, you still need to employ a thick compensation wire.

- Mechanical stress on the cable and the element is to be avoided.

- Twisted-pair cable should be used with long thermoelement connections.

- Sudden temperature changes are to be avoided.

- Users should always observe the maximum temperature specified for the thermoelement, as well as the much lower value for the compensation line.

- The mechanical loading of the element is to be matched to the application.

- Despite the use of a low-noise measurement amplifier inside the MAX6675, the thermoelement, all wires and connections should be kept far removed from of electrical noise sources.

Reprinted Url Of This Article: http://www.seekic.com/blog/project_solutions/2011/08/10/THERMOELEMENTS__(2).html

Print this Page | Comments | Reading(440)

Article Categories

New published articles

· Imagination works with TSMC to develop FinFET process

Author:Ecco Reading(33516)

· XMOS pushes event-driven MCUs with lower price

Author:Ecco Reading(3534)

· Intel brings upgraded 32-nm SoC for smartphones

Author:Ecco Reading(3250)

· Micron pushes TLC 128-Gbit NAND flash

Author:Ecco Reading(3816)

· Intel will stop supplying desktop motherboards

Author:Ecco Reading(5341)

· Processor market was expected to regain strength in 2013

Author:Ecco Reading(3318)

· It was reported that TSMC sales fall steeply

Author:Ecco Reading(3474)

· Cisco, NXP work with auto wireless startup

Author:Ecco Reading(3620)

· Micron was impacted by manufacturing glitch

Author:Ecco Reading(4017)

· China can make 22-nm transistor by themselves

Author:Ecco Reading(3819)

· Chip market rebound is coming, according to survey

Author:Ecco Reading(3760)

· Sony, Toshiba will spend more on chips, iSuppli reports

Author:Ecco Reading(3790)

· Qualcomm becomes the 13th company to join NFC Forum board

Author:Ecco Reading(6103)

· TSMC increases building work for FinFET fab

Author:Ecco Reading(3778)

· TI plans to cut 1,700 jobs in OMAP shift

Author:Ecco Reading(4587)