Project Solutions

THERMOELEMENTS (1)

Published:2011/8/10 3:22:00 Author:Phyllis From:SeekIC

By Thomas Johann Seebeck

Easy processing with the MAX6675

Design engineers like to use thermoelements when it comes to probing around in really wide temperature ranges. Modern integrated circuits are available that act as sensor interfaces to a microcontroller.

The operation of thermoelements is based on the See-beck effect: a temperature difference across a wire causes movement of free electrons. The amount of charge displacement is dependent on the electrical properties of the wire.

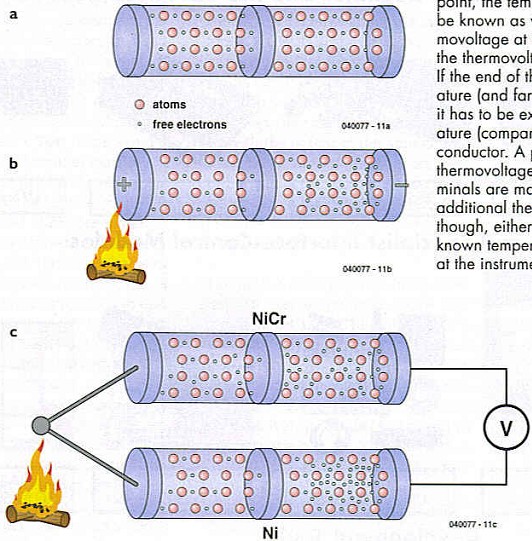

As illustrated in Figure 1, thermal energy is applied to electrons normally moving inside a crystal grid structure. The applied energy causes the electrons to move faster and eventually diffuse from the hot to the cold end. There they slow down again, releasing their energy. As electrons concentrate at the cold end, a negative electrode is formed relative to the hot end. At the same time an electrical field is established maintaining a dynamic balance between the electrons.

If the voltage between the hot and the cold end is to be measured, one thing you have to do is connect the hot end to an electrical conductor that’s also exposed to the temperature changes. If this second conductor has the same electrical properties as the first one, then no voltage can be measured between the charge density points. However if two different conductors are used, a voltage exists between the two ’cold’ ends that’s dependent on the temperature difference and the electrical properties of both conductors.

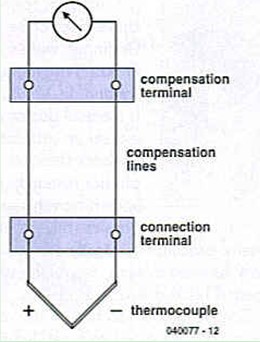

In the test arrangement shown in Figure 2, no absolute thermovoltage can be measured, only differential levels. In order to establish the temperature at the measurement point, the temperature at the connection terminal has to be known as well as constant. Datasheet values like ’thermovoltage at 200 °C’ always relate to a comparison to the thermovoltage at 0 °C.

If the end of the thermoelement is at an unknown temperature (and far removed from the measurement electronics) it has to be extended right into the area of known temperature (comparison point), using a special compensating conductor. A problem arises with the measurement of thermovoltage using an instrument whose connection terminals are made of a different material. These create two additional thermoelements, which may be compensated, though, either by keeping the comparison point at a known temperature, or perform an appropriate correction at the instrument terminals.

Thermoelements

The voltage caused by the thermoelectric effect is very small at just a few millivolts per Kelvin, depending on the metal or alloy combination. As a result, thermoelements are not used for measurements in the range -30 CC to +50 =C because the temperature difference with the reference is simply too small to ensure a reliable signal. Consequently thermoelements are typically used for measurements up to 1000 °C.

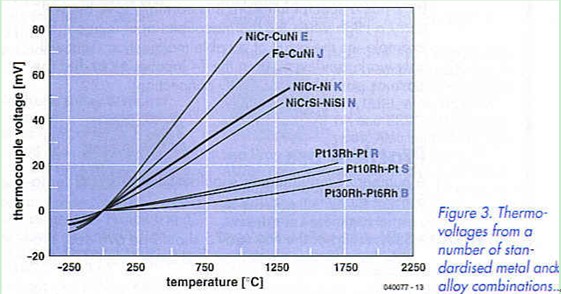

From the multitude of metal and alloy combinations, a few have been selected and their voltage series laid down in DIN standard EN 60584 (types L and U are obsolete and now replaced by J and T). The element types differ in respect of maximum temperature and their characteristics as shown in Figure 3. The maximum temperature is the highest value at which the tolerance is maintained. Under ’defined up to’ you find the highest temperature at which the ihermovoltage complies with the standard. With the thermocouples listed, the first material is always the positive terminal.

As you can see from the response curves, the voltage supplied by thermoelements is not a perfectly linear function of applied temperature. If you want really accurate readings, then a linearization circuit is required specifically designed for each type of element. Figure 4 shows that for a K element the maximum deviation from the linear function is no more than 0.5 K a 750 °C. If you can live with such a small error in a relatively narrow measurement range, then a complex linearization circuit is not in order.

Reprinted Url Of This Article: http://www.seekic.com/blog/project_solutions/2011/08/10/THERMOELEMENTS__(1).html

Print this Page | Comments | Reading(537)

Article Categories

New published articles

· Imagination works with TSMC to develop FinFET process

Author:Ecco Reading(33516)

· XMOS pushes event-driven MCUs with lower price

Author:Ecco Reading(3534)

· Intel brings upgraded 32-nm SoC for smartphones

Author:Ecco Reading(3250)

· Micron pushes TLC 128-Gbit NAND flash

Author:Ecco Reading(3816)

· Intel will stop supplying desktop motherboards

Author:Ecco Reading(5341)

· Processor market was expected to regain strength in 2013

Author:Ecco Reading(3318)

· It was reported that TSMC sales fall steeply

Author:Ecco Reading(3474)

· Cisco, NXP work with auto wireless startup

Author:Ecco Reading(3620)

· Micron was impacted by manufacturing glitch

Author:Ecco Reading(4017)

· China can make 22-nm transistor by themselves

Author:Ecco Reading(3819)

· Chip market rebound is coming, according to survey

Author:Ecco Reading(3760)

· Sony, Toshiba will spend more on chips, iSuppli reports

Author:Ecco Reading(3790)

· Qualcomm becomes the 13th company to join NFC Forum board

Author:Ecco Reading(6103)

· TSMC increases building work for FinFET fab

Author:Ecco Reading(3778)

· TI plans to cut 1,700 jobs in OMAP shift

Author:Ecco Reading(4587)