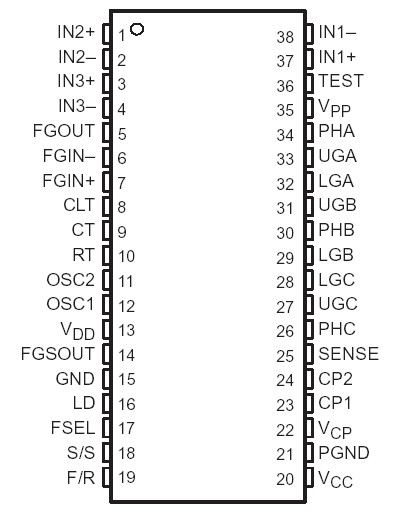

TPIC43T01: Features: Precision Phase Lock Loop Motor RPM Control With Embedded DSP Filter Algorithm for Loop Compensation EEPROM Registers for User Adjustment of PLL Loop Gain and DSP Filter Coefficients (P...

floor Price/Ceiling Price

- Part Number:

- TPIC43T01

- Supply Ability:

- 5000

Price Break

- Qty

- 1~5000

- Unit Price

- Negotiable

- Processing time

- 15 Days

SeekIC Buyer Protection PLUS - newly updated for 2013!

- Escrow Protection.

- Guaranteed refunds.

- Secure payments.

- Learn more >>

Month Sales

268 Transactions

Payment Methods

All payment methods are secure and covered by SeekIC Buyer Protection PLUS.

TPIC43T01 Data Sheet

TPIC43T01 Data Sheet