Features: DC Fan Drive Speed Control With No External Power Drive Stage Required

11% to 100% PWM Range Adjustable Via 02.5 V DC Control Voltage Suited for Cooling Fan Applications Requiring Variable RPM to Reduce Noise and/or Increase MTBF

Speed Control Capability With Either DC or PWM Input Signal for Greater System-Level Flexibility

Sleep-State Mode to Eliminate External Fan ON/OFF Power Device Suited for Cooling Fans in Instantly Available PCs

Thermal Shutdown Protection

High Impedance VPWM Input for Speed Control of Multiple Fans With a Single Signal

Locked Rotor Protection (THMC40, THMC41) With Open-Drain Output Indication (THMC41)

Open-Drain Tachometer Signal Valid Over Entire RPM Range (THMC40)

Noise Immune Signal Conditioning to Allow Use of Low-Cost Hall Effect Position

Sensor

Patented High Efficiency Drive Topology With Integrated Low RDS(ON) LDMOS Output Drivers

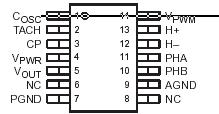

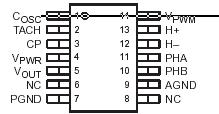

Pinout Specifications

SpecificationsSupply voltage input, VPWR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 V

High-side driver, PWM output voltage, VOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 V

Low-side drivers, phase A and B output, VPHA, VPHB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 V

Hall sensor amplifier input voltage, VH+, VH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 V

PWM duty cycle control input voltage, VPWM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 V

Open-drain tachometer output voltage (THMC40), VTACH, or open-drain RD output voltage

(THMC41), VRD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 V

Oscillator capacitor voltage, VCOSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 V

Charge pump capacitor voltage, VCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 V

Continuous high-side PWM output source/sink current, IOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 A

Continuous low-side PWM output sink current, IPHA, IPHB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 A

Junction-to-case thermal resistance, RJC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26.9°C/W

Junction-to-ambient thermal resistance , RJA (see Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122.3°C/W

Continuous power dissipation at 25°C , PD (see Note 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1022 mW

Power derating factor above 25°C ambient , PDERATING (see Note 4) . . . . . . . . . . . . . . . . . . . . .8.18 mW/°C

Operating case temperature range, TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30°C to 80°C

Storage temperature range, Tstg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55°C to 150°C

Maximum junction temperature, T J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

Lead temperature (soldering, 10 sec), TLEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300°C

DescriptionThe THMC40 and THMC41 are 2-phase, dc brushless motor (BLM) drive and control devices intended for use with 12-Vdc cooling fans. THMC40 and THMC41 include a high-efficiency PWM drive topology using integrated 0.5-W (typical) LDMOS drivers, plus a speed control input stage to provide the industry's first solution for efficient speed control inside dc cooling fans. This patented solution eliminates the need for power drive components on the main system board, thus reducing printed-circuit board (PCB) component count, PCB space, and assembly time. This solution of THMC40 and THMC41 also offers other advantages over the two commonly used fan speed control methods, adjustable external dc supply voltage, and adjustable external PWM drive duty cycle.

Unlike other methods which control speed external to the cooling fan, the THMC40 and THMC41 high-efficiency PWM drive stage adjusts only the level of motor phase winding power. All other circuitry inside the fan obtains power from the fixed dc voltage fan supply. This method eliminates the typical problem associated with an external dc voltage regulation method causing loss of headroom to internal control circuitry of THMC40 and THMC41 at low fan supply voltage and the resulting limitation of low-speed operation to 940%. The PWM drive method employed by the THMC40 and THMC41 also reduces fan supply power consumption over the external linear regulation method, which has V*I power loss due to the voltage drop across the regulator.

An external PWM drive method disrupts power to the motor and also to all internal fan circuitry. The THM40 and THMC41 solution maintains all signal integrity with phase drive commutation and tachometer, while providing

reliable low speed fan operation down to 11% PWM. This method allows fan health monitoring over the full fan speed range.

THMC40 Data Sheet

THMC40 Data Sheet