Pinout SpecificationsStorage Temperature

SpecificationsStorage Temperature

Plastic Packages . . . . . . . . . . . . . . . 65°C to +150°C

Ambient Temperature

with Power Applied. . . . . . . . . . . . . . 55°C to +125°C

Voltage with Respect to Ground

VCC (Note 1) . . . . . . . . . . . . . . . .2.0 V to +7.0 V

A9, OE#, and

RESET# (Note 2). . . . . . . . . . . .2.0 V to +12.5 V

All other pins (Note 1) . . . . . . . . .0.5 V to +7.0 V

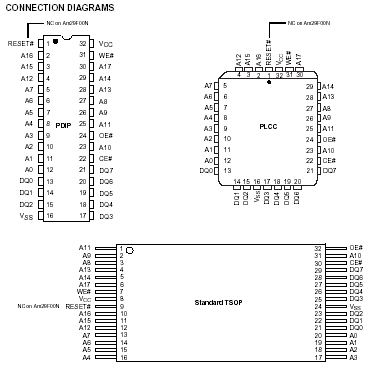

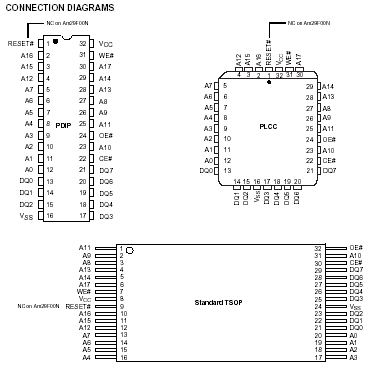

Output Short Circuit Current (Note 3) . . . . . . 200 mADescription The Am29F002 Family consists of 2 Mbit, 5.0 volt-only Flash memory devices organized as 262,144 bytes. The Am29F002 offers the RESET# function, the Am29F002N does not. The data appears on DQ7 DQ0. The device is offered in 32-pin PLCC, 32-pin TSOP, and 32-pin PDIP packages. This device is designed to be programmed in-system with the standard system 5.0 volt VCC supply. No VPP is required for write or erase operations. The device can also be programmed in standard EPROM programmers.

The standard Am29F002N device offers access times of 55, 70, 90, and 120 ns, allowing high speed microprocessors to operate without wait states. To eliminate bus contention the device has separate chip enable (CE#), write enable (WE#) and output enable (OE#) controls.

The device requires only a single 5.0 volt power supply for both read and write functions. Internally generated and regulated voltages are provided for the program and erase operations.

Am29F002N is entirely command set compatible with the JEDEC single-power-supply Flash standard. Commands

are written to the command register using standard microprocessor write timings. Register contents serve as input to an internal state-machine that controls the erase and programming circuitry. Write cycles also internally latch addresses and data needed for the programming and erase operations. Reading data out of the device is similar to reading from other Flash or EPROM devices.

Device programming occurs by executing the program command sequence. This initiates the Embedded Program algorithm-an internal algorithm that automatically times the program pulse widths and verifies proper cell margin.

Device erasure occurs by executing the erase command sequence. This initiates the Embedded Erase algorithm-an internal algorithm that automatically preprograms the array (if it is not already programmed) before executing the erase operation. During erase, the device automatically times the erase pulse widths and verifies proper cell margin.

The host system can detect whether a program or erase operation is complete by reading the DQ7 (Data# Polling) and DQ6 (toggle) status bits. After a program or erase cycle has been completed, the device is ready

to read array data or accept another command.

The sector erase architecture allows memory sectors to be erased and reprogrammed without affecting the data contents of other sectors. Am29F002N is fully erased when shipped from the factory.

Hardware data protection measures include a low VCC detector that automatically inhibits write operations during power transitions. The hardware sector protection feature disables both program and erase operations in any combination of the sectors of memory. This can be achieved via programming equipment.

The Erase Suspend feature enables the user to put erase on hold for any period of time to read data from, or program data to, any sector that is not selected for erasure. True background erase can thus be achieved.

The hardware RESET# pin terminates any operation in progress and resets the internal state machine to reading array data. The RESET# pin may be tied to the system reset circuitry. A system reset would thus also reset the device, enabling the system microprocessor to read the boot-up firmware from the Flash memory. (This feature is not available on the Am29F002N.)

The system can place the device into the standby mode. Power consumption is greatly reduced in this mode.

AMD's Flash technology combines years of Flash memory manufacturing experience to produce the highest levels of quality, reliability and cost effectiveness. The device electrically erases all bits within a sector simultaneously via Fowler-Nordheim tunneling. The data is programmed using hot electron injection.

Am29F002N Data Sheet

Am29F002N Data Sheet