Project Solutions

Sensors Go Systematic (4)

Published:2011/7/28 5:21:00 Author:Amy From:SeekIC

Modular construction

Despite iis considerable success, there is a problem with microsystem technology, which is that the large front-end development costs can only be recovered if the components are produced in large quantities. This is difficult to achieve for small and medium-sized sensor manufacturers.

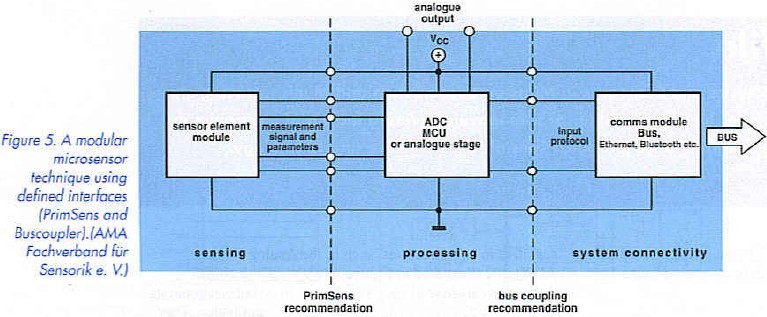

One solution to this problem is to construct the sensors in modular form using several independent functional blocks, which can then easily achieve large production volumes. A concept employing three modules, which has been developed by AMA Fachverband fur Sensorik e. V. (www.ama-serh sorik.de) in close cooperation with industry, is shown in Figure 5. It consists of the following modules: 1) the measurement module with the sensor element and signal conditioning. 2) a microcontroller for additional signal processing (including digitising), and 3) a bus coupler if necessary. The modules are separated by two standardized interfaces. The first interface is called ‘PrimSens’, and the second is called "Buscoupler". The first products of this type were shown recently at the Hanover Fair.

Another modular concept defines a component system with small, square circuit boards with dimensions of 10 x 10 to 45 x 45 mm. which can be stacked on top of each other (www.match-x.org).

Interference-free measurement without electricity

The sensors we have examined up this point are all ’normal’ sensors that work with electrical cables, but there are some places where it is not possible to run such cables, such as where there is an explosion hazard or where there is a risk of voltage discharge in a high-voltage installation - or in environments w here there are strong electromagnetic fields, such as in radio transmitters or electrical generators.

In such situation, a different approach must be taken. A highly promising technique is optical measurement using light instead of electricity. The light is conveyed by a glass or plastic optical fibre to the measurement location, where it is affected by the quantity to be measured and then returned via the same optical fibre or a second fibre. The evaluation instrument determines the measurement value from the returning light. An example is the Lumitherm instrument made by the US company Ipitek, which transmits light pulses from an LED through a fibre to a measurement probe, where they excite luminescence in a fluorescent material. The duration of the luminescence depends on the temperature, and this effect is exploited to make measurements using the luminescent light returned to the instrument. Systems of diis sort, in which the fibre only acts to convey the light, are called "extrinsic’ ftbre-opuc systems.

Reprinted Url Of This Article: http://www.seekic.com/blog/project_solutions/2011/07/28/Sensors_Go_Systematic_(4).html

Print this Page | Comments | Reading(385)

Article Categories

New published articles

· Imagination works with TSMC to develop FinFET process

Author:Ecco Reading(33527)

· XMOS pushes event-driven MCUs with lower price

Author:Ecco Reading(3534)

· Intel brings upgraded 32-nm SoC for smartphones

Author:Ecco Reading(3250)

· Micron pushes TLC 128-Gbit NAND flash

Author:Ecco Reading(3816)

· Intel will stop supplying desktop motherboards

Author:Ecco Reading(5341)

· Processor market was expected to regain strength in 2013

Author:Ecco Reading(3318)

· It was reported that TSMC sales fall steeply

Author:Ecco Reading(3474)

· Cisco, NXP work with auto wireless startup

Author:Ecco Reading(3620)

· Micron was impacted by manufacturing glitch

Author:Ecco Reading(4017)

· China can make 22-nm transistor by themselves

Author:Ecco Reading(3820)

· Chip market rebound is coming, according to survey

Author:Ecco Reading(3761)

· Sony, Toshiba will spend more on chips, iSuppli reports

Author:Ecco Reading(3790)

· Qualcomm becomes the 13th company to join NFC Forum board

Author:Ecco Reading(6105)

· TSMC increases building work for FinFET fab

Author:Ecco Reading(3778)

· TI plans to cut 1,700 jobs in OMAP shift

Author:Ecco Reading(4587)