Industry News

Low-Ag and No-Ag Lead-Free Solders Highlighted

Published:2011/12/30 0:43:00 Author:Amy From:SeekIC

Nihon Superior, a supplier of advanced soldering materials, has presents the effectiveness of Cu and Ni as the crucial elements in constructing a stable IMC layer in lead-free soldering.

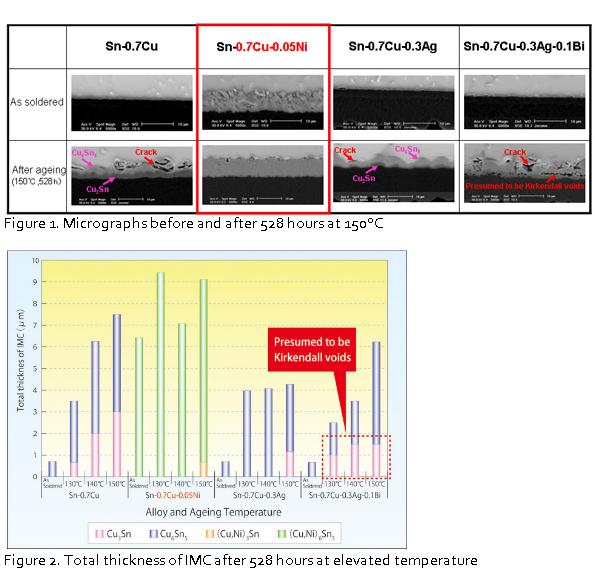

As the micrographs below, the fluxed copper/OSP test boards were exposed to the solders for five seconds in a mini-wave machine with a pot temperature of 255°C. It was found that after 528 hours at 150°C, the intermetallic compound on the board soldered with Sn-0.7Cu-0.05Ni was smoother with slower growth of Cu3Sn and no cracking. By contrast, the IMC layer in Sn-0.7Cu-0.3Ag and Sn-0.7Cu-0.3Ag-0.1B with additions of 0.3 Ag and 0.3 Ag+0.1Bi was uneven with growth of Cu3Sn and cracking (Figure 2).

Based on Sn-0.7Cu-0.05Ni, Nihon Superior’s SN100C solder also integrates a Ge addition as an antioxidant and flow promoter.

Silver-free, lead-free solder, SN100C now has a track record of more than 12 years of successful delivery of high productivity and high reliability. The first of the new SN100C Advantage Series, SN99CN, builds on the strengths of the Sn-Cu-Ni formulation of SN100C with a controlled addition of silver. Both SN100C and SN99CN include Cu and Ni to form the stable IMC (Cu,Ni)6Sn5.

Reprinted Url Of This Article: http://www.seekic.com/blog/IndustryNews/2011/12/30/Low_Ag_and_No_Ag_Lead_Free_Solders_Highlighted.html

Print this Page | Comments | Reading(440)

Article Categories

New published articles

· Imagination works with TSMC to develop FinFET process

Author:Ecco Reading(33507)

· XMOS pushes event-driven MCUs with lower price

Author:Ecco Reading(3534)

· Intel brings upgraded 32-nm SoC for smartphones

Author:Ecco Reading(3250)

· Micron pushes TLC 128-Gbit NAND flash

Author:Ecco Reading(3816)

· Intel will stop supplying desktop motherboards

Author:Ecco Reading(5341)

· Processor market was expected to regain strength in 2013

Author:Ecco Reading(3318)

· It was reported that TSMC sales fall steeply

Author:Ecco Reading(3474)

· Cisco, NXP work with auto wireless startup

Author:Ecco Reading(3620)

· Micron was impacted by manufacturing glitch

Author:Ecco Reading(4017)

· China can make 22-nm transistor by themselves

Author:Ecco Reading(3819)

· Chip market rebound is coming, according to survey

Author:Ecco Reading(3760)

· Sony, Toshiba will spend more on chips, iSuppli reports

Author:Ecco Reading(3790)

· Qualcomm becomes the 13th company to join NFC Forum board

Author:Ecco Reading(6103)

· TSMC increases building work for FinFET fab

Author:Ecco Reading(3778)

· TI plans to cut 1,700 jobs in OMAP shift

Author:Ecco Reading(4587)